- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Chutes and Exhauster Fan Repair

Chutes, troughs, cyclones, fly ash exhauster fans, etc. typically are damaged due to abrasive wear. Repairs can be effectively made and further damage thwarted using Metalink wear resistant coatings. The repairs exampled below can be used in many different circumstances for wear repair.

Chutes

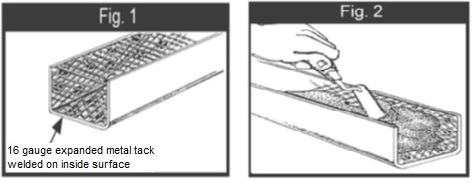

1) Tack weld 16 gauge expanded metal to the inside surface, making sure the expanded metal closely follows the designed shape of the chute. Tacks should be about every 4 to 6 inches. (Fig. 1)

2) Once expanded metal is firmly in place, sandblast the entire surface. Degrease thoroughly with Metal Prep II™.

3) Apply Ceramic Bead Polymer to the chute, pressing it in to the expanded metal. Build up the surface at least ¼” thick.

4) Trowel the surface smooth and allow to cure according to the data sheet. (Fig. 2)

Fly Ash Exhauster Fans

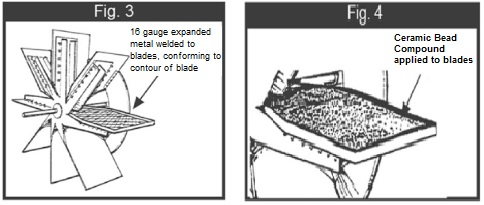

1) Tack weld 16 gauge expanded metal to each blade, making sure the expanded metal closely follows the designed shape of the blade. Tacks should be about every 4 to 6 inches. (Fig. 3)

2) Cut ¼” thick by 1” wide flat bar to make borders for each blade. Weld the flat bar into place.

3) Sandblast the fan blade surfaces. Degrease with Metal Prep II™.

4) Apply Ceramic Bead Polymer to the chute, pressing it into expanded metal. Build up the surface at least ¼” thick, paying particular attention to the corners, making sure all voids are filled. Trowel smooth.

5)After the compound applied to the blades has cured, apply Machinable Repair™ to the back of each blade to balance the assembly.

Comments

No posts found