- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Pump Housing Crack Repair

1) Thoroughly clean repair surface at last 2" on all sides of cracks or holes in accordance with Metals Preparation Guide. Degrease with Metal Prep II™.

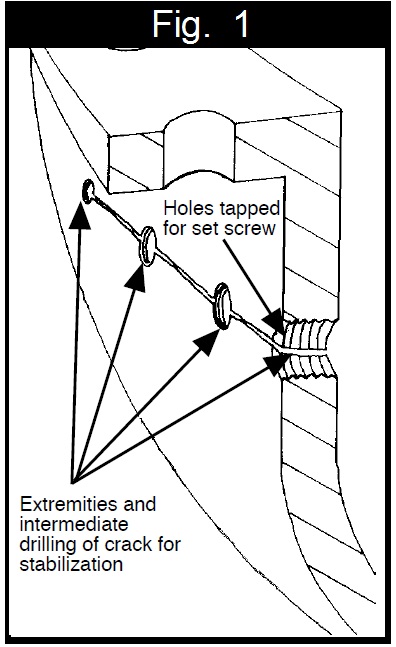

2) To stabilize the crack, each end of the crack must be drilled. For hairline cracks, the holes should be drilled 3/16" diameter. For wider cracks, drill the holes 3/16" wider than the width of the crack. (Note: it is very important that the holes be drilled at the extremities of the crack. It might be necessary to use a crack detection fluid to determine this. If so, it will be necessary to re-clean and prepare surface so that all the crack detection fluid has been completely removed prior to epoxy application.)

3) If the crack is longer than 6", drill holes in 3" to 4" intervals along the crack. (Fig. 1)

4) Tap all the holes as follows: for hairline cracks: 1/4”-20 thread. Larger cracks: width of crack plus 1/4”.

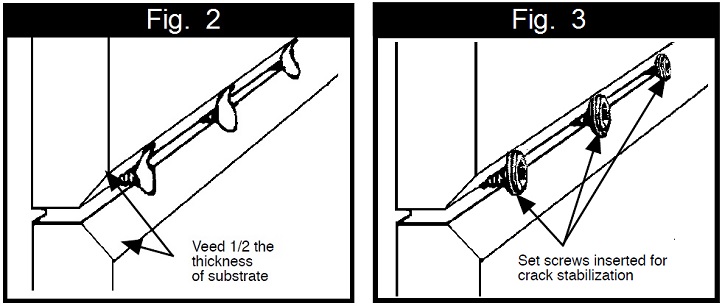

5) "V" out the crack using a grinder, drill, or rotary file. A good angle would be optimum. The "V" should be cut to 1/2 the thickness of the housing wall (Fig. 2).

6) Insert an appropriate sized set screw into the threaded holes, allowing the top to extend lightly into the "V" area (Fig. 3).

7) Apply Machinable Repair™ or Fas-Steel 4™ to the crack area and complete repair as outlined in Cracked Engine Block Repair, step 7 through step 9 .

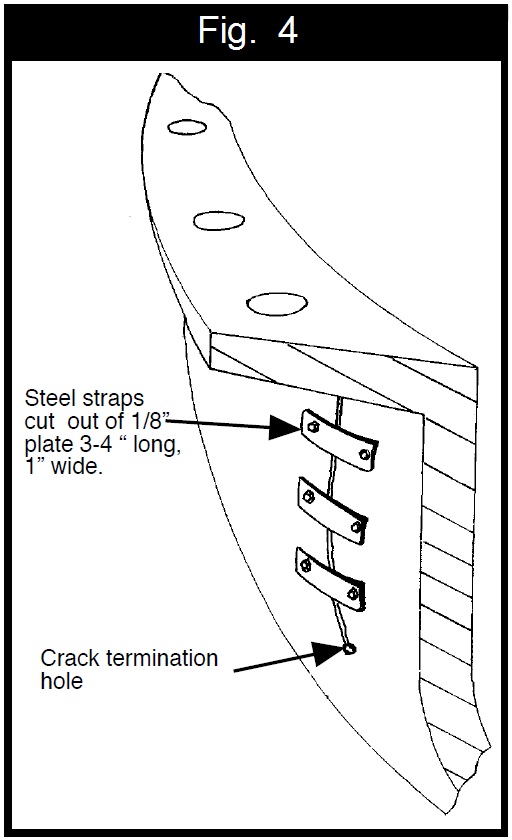

Some cracks are positioned such that vibration will cause twisting of the body in the crack area, allowing expansion of the crack opening. This requires a different stabilization procedure ( as follows): (See Fig. 4)

1) Terminate each end of the crack by drilling holes as described in the above procedure. However, it is not necessary to tap the holes

2) From 1/8" plate, cut steel stripe approximately 3-4 inches long by 1" width. Drill 5/16" holes on each end of the stripe. (Enough of these should be made to place every 3" along the crack.)

3) Drill holes 3/16" of an inch on each side of the crack using the steel strips as a template. Tap each hole with %-20 threads.

4) "V" out the entire crack as described in previous procedure.

5) Coat enough 1/4-20 full thread cap screws for each hole drilled and tapped on each side of the crack with Metalink Thread Locker™. Insert them through the steel straps and into the housing and tighten.

6) Now apply Machinable Repair™ or Fas-Steel 4™ to the crack, following the procedure outlined in Cracked Engine Block Repair, step 7 through step 9 . Let compound cure fully before returning to service.

Comments

No posts found