- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Keyway Repair

One of the best features of Metalink Machinable Repair™ is its incredible compression strength. This allows repairs of Keyways. Typical repair methods are as follows:

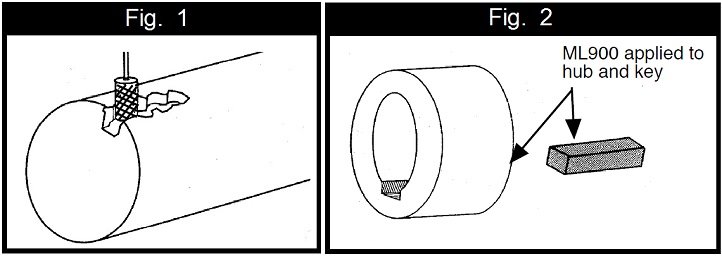

1) Remove any fatigued metal from keyway and file off rough edges. A rotary file works well for this step. (Fig. 1) Abrade surface by brushing, sanding, or grit blasting. Clean and degrease all surfaces with Metal Prep II™.

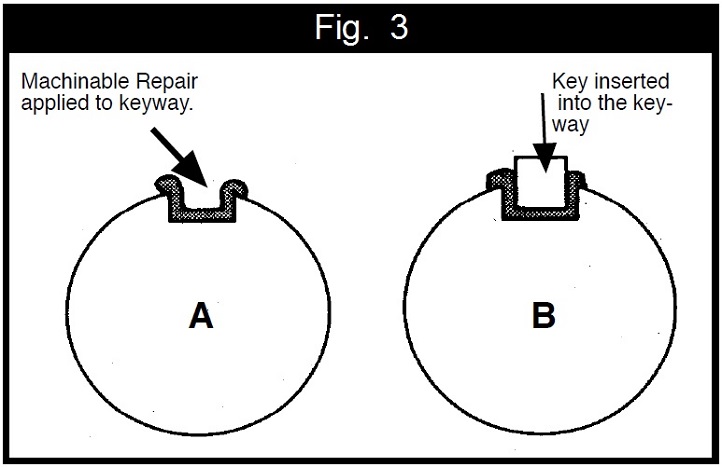

2) Coat new keys and inside of hub assembly with ML900 Silicone Lubricant & Release Agent. (Fig. 2)

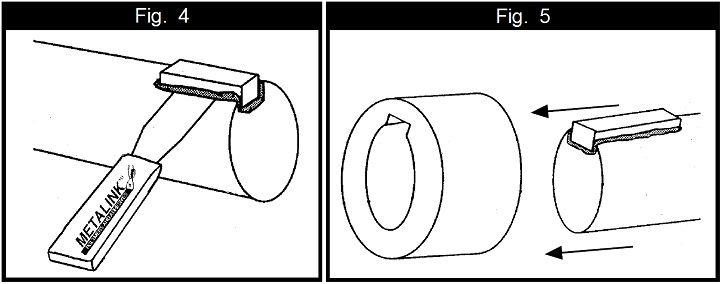

3) Apply Machinable Repair™ to sides and corners of keyway. Apply only a thin layer to bottom. (Fig. 3A)

4) Insert the new key, tapping lightly to seat it. (Fig. 3B)

5) With a putty knife, remove excess Machinable Repair™ from the side of the keyway. (Fig. 4)

6) Align the key with the keyway in the hub and insert the shaft into the hub assembly. Allow it to remain until Machinable Repair™ is fully cured. (Fig. 5)

Note: For larger shafts, the entire keyway may be filled in and re-machined.

Comments

No posts found