- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Pump Volute Repair

INTERNAL

1) Clean and abrade surfaces according to the Metals Preparation Guide. Degrease thoroughly with Metal Prep II™.

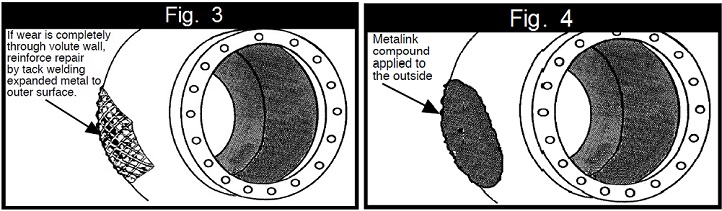

2) Using a thin flexible applicator. fill in and build up gouges and worn areas using Machinable Repair™ or Fas-Steel 4™ (Fig. 1).

3) Apply the remaining Metalink compound into the volute making sure the contour is followed. Smooth the surface by wetting the applicator with water (optional). Allow to cure according to technical guide.

4) If needed, the surface can be built up slightly more than the original contour. and then ground back to original shape using a grinding disk and sanding wheel after it has cured.

5) Completely Coat inside Volute area with a thin layer Metalink Brush-on Ceramic™ (Fig. 2). This extends operating life of pump by reducing friction and increasing efficiency of the pump.

EXTERNAL

For external damage on pumps, repair can be accomplished by doing the following:

1) Prepare outside surface 3" beyond the repair area in accordance to Metals Preparation Guide. Thoroughly degrease using Metal Prep II™.

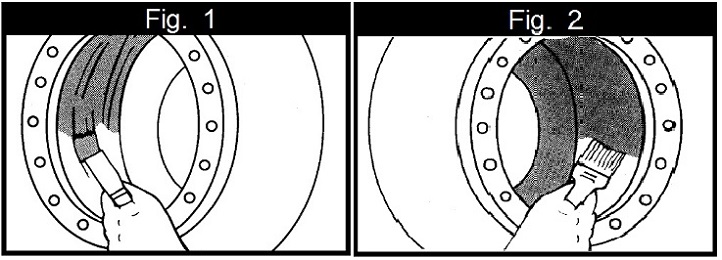

2) If housing is worn completely through, tack weld 16 gauge or heavier expanded metal onto the housing. covering the hole. Re-clean area along the expanded metal and degrease using Metal Prep II™ again (Fig. 3).

3) Apply Machinable Repair™ or Fas-Steel 4™ to the area (the inside first if completely worn through, as outlined in guideline for internal volute repair.)

4) Apply to outside area making sure air bubbles are squeezed out, and that the compound is worked well into the expanded metal and integrated with the compound applied on the inside (if applicable) (Fig. 4).