- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Shaft Repair

Shafts that are damaged due to metal to metal friction may be repaired using a Metalink Machinable Repair™ Compound, as long as the entire contact surface is not worn away or it is being used for a bearing race fit. If the damaged area extends the entire length of the bearing, the following repair can be utilized but should be considered only temporary.

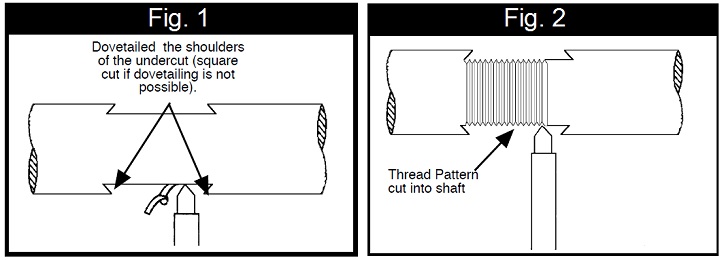

1) Prepare the shaft by undercutting the worn area according to the following guide: shaft diameter 1/2" to 1"-1/16 undercut; 1" to 3"-1/8" undercut (Fig.1). Dove-tail or square cut the ends. If the shaft is already worn to the recommended depth, go to step two.

2) Cut a thread pattern into the shaft, shallow on small diameter shafts, deeper for larger diameters (Fig.2).

3)Clean thoroughly with Metal Prep II™ Degreaser. Apply a very thin layer of ML400 Machinable Repair™ to the threaded area, forcing the material into the threads.

4) With shaft turning slowly on lathe, apply more Machinable Repair™, building up the repair area slightly higher than the shaft (Fig. 3).

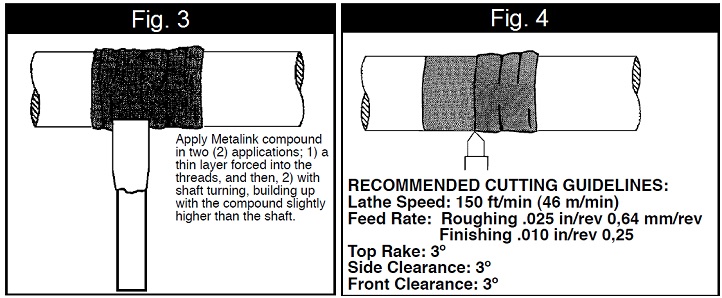

5) Allow the Machinable Repair™ to cure fully according to technical guidelines. Note: Allowing the lathe to continue to turn very slowly while curing will reduce the chance of the material sagging and creating a low spot.

6) Machine the surface with carbide tools (Fig.4). A fine finish may be acquired by polishing with abrasive hand pads, or a very fine emery cloth. Lubricate the shaft before returning to service.

Comments

No posts found