- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

-

Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

Flange Repair

Severe Pitting/Corrosion – One Side

Severe Pitting/Corrosion – Both Sides

Flanges that have a small cut or gouge may be repaired in the following manner:

1) Prepare repair area according to Metals Preparation Guide. Afterwards, degrease surface thoroughly with Metal Prep II™.

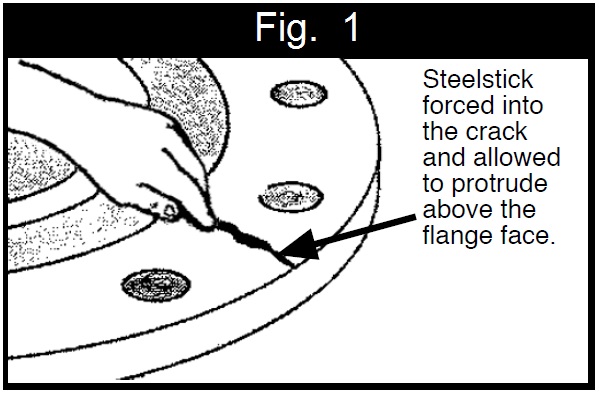

2) Mix a small amount of Steelstick™ according to instructions. Force the material well into the cavity, and allow a slight protrusion above the face of the flange. (Fig. 1)

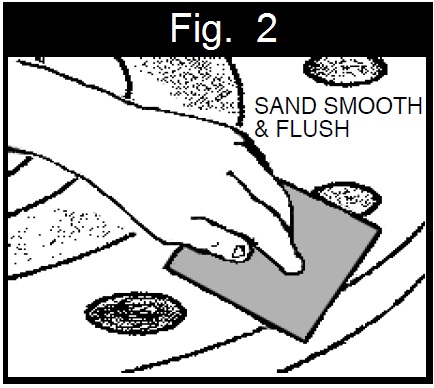

3) After Steelstick™ has set, (typically 15 - 20 minutes), sand the surface smooth using 400 to 600 grit wet cut abrasive. (Fig. 2)

4) Flange is now ready to return to surface.

Severe Pitting/Corrosion -One Side

1) Prepare surface of pitted flange according to the Metals Preparation Guide. Thoroughly clean and degrease with Metal Prep II™.

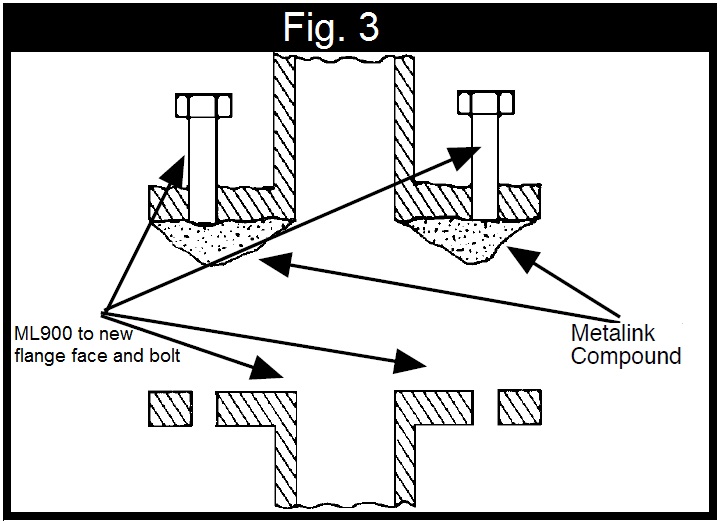

2) Apply ML900 Silicone Lubricant & Release Agent to surface of the good or new flange. Also apply it to the assembly bolts and then insert them into the flange holes.

3) Apply ML400 Machinable Repair™ to the surface of the pitted flange at least 1/16" thick. (Fig.3)

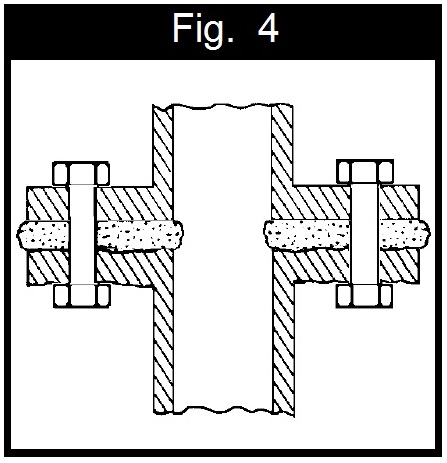

4) Assemble both flanges and bolt together. Wipe off excess material and allow curing fully. (Fig. 4)

5) Disassemble and clean/grind around bolt holes. Flange is now ready to return to service.

NOTE: This repair should not be attempted on flanges with operation temperatures higher than 300°F.

Severe Pitting/Corrosion -Both Sides

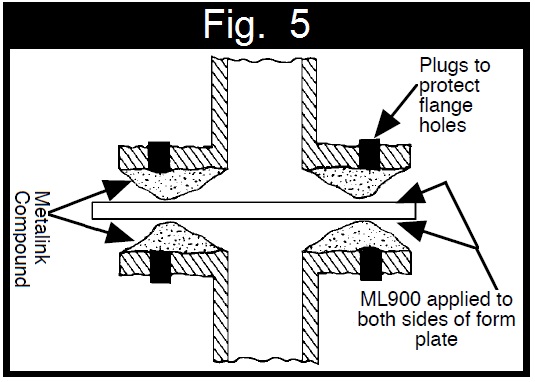

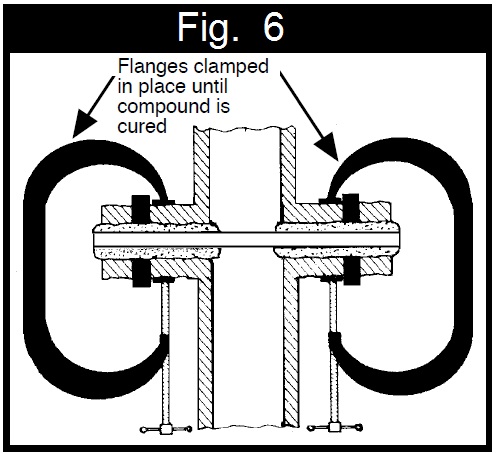

Flanges that are scored or pitted on both surfaces may be repaired in the following manner: (Fig.'s 5 & 6):

1) Abrade surface of pitted flanges by sanding, grinding, power-brushing, or grit blasting. Clean with Metal Prep II™ Degreaser.

2) Plug all bolt holes with corks, wooden plugs or putty.

3) Prepare a flat, smooth metal plate that extends beyond the diameter of the flanges to act as a mold for the new gasket surface. Coat this with ML900 Silicone Lubricant & Release Agent.

4) Coat both pitted flange surfaces with ML400 Machinable Repair™ at least 1/16" thick.

5) Install smooth metal plate between flanges, clamp together, wipe off excess material and allow curing fully.

6) Disassemble and clean/grind areas around bolt holes. Install new gasketing and return to service.

Note: This repair should not be attempted on flanges with operating temperatures higher than 300°F.

Comments

No posts found